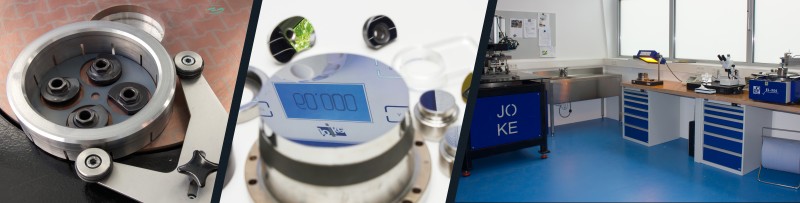

The company joke - Over 80 years of tradition and experience

Take a look at the over 80 years of development of joke Technology GmbH.

Introduction of the ENESKAmarker 300 - Laser Marking System

Laser marking with optimal durability for component identification. Without exerting force, contactless and fast - making it easy to mark thin-walled, polished, and finished components.

Expected since many years. Now available: ENESKAmobile - battery-powered deburring, grinding and polishing system

The handy, battery operated ENESKAmobile polishing system is the ideal tool for setters and toolmakers – anywhere that grinding, polishing, milling or deburring is required. Robust and shock-resistant, it can be used flexibly in any place, and away from the work bench.

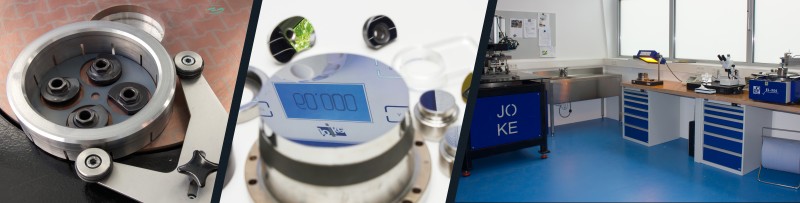

Milestone for joke: ENESKApostprocess - workstation for secure postprocessing

What it means is a dense, completely enclosed work area, equipped with electrical and pneumatic tools as well as powerful suction devices.

New on the market: ENESKAsonic - Ultrasonic System

The most innovative advancement in the field of ultrasonic technology, ENESKAsonic. Powerful high-tech next-generation for finest material removal. In ultrasonic polishing, an abrasive tool is vibrated at high speed, allowing precise material removal and delicate work.

Introduction of the ENESKAmarker 300 - laser marking system

Laser marking with optimal durability for component identification. Without exerting force, contactless and fast - making it easy to mark even thin-walled, polished, and finished components.

2020

Die meisten eingesetzten Materialien setzen beim Postprocessing lungengängige Stäube frei. Sie werden unter anderem für Krebs und Herz-Kreislauf-Erkrankungen verantwortlich gemacht.

2021

Introduction of the ENESKAmarker 300 - Laser Marking System

Laser marking with optimal durability for component identification. Without force, contactless, and fast - making it easy to mark even thin-walled, polished, and finished components.

2020

Long awaited and now finally here: ENESKAmobile - Battery-powered Deburring, Grinding, and Polishing System

The handy battery-powered polishing system ENESKAmobile is the ideal tool for the setup person or toolmaker - no matter where you want to grind, polish, mill, or deburr. Robust and shock-resistant, it is flexible for use at any location, away from the workbench.

2019

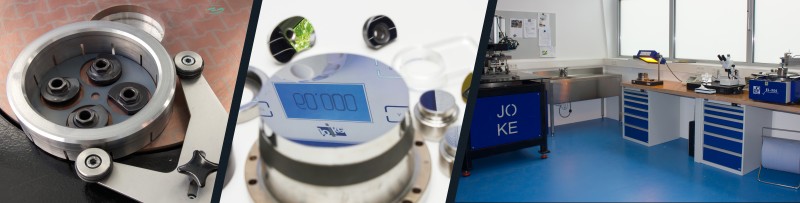

Milestone for joke: ENESKApostprocess - Workstation for Safe Postprocessing

Behind ENESKApostprocess lies a closed, fully encapsulated workspace, equipped with electric and pneumatic tools as well as powerful extraction devices.

2018

New development in the laser sector - mobile Laser Welding System ENESKAlaser 1500

Repairing shapes/components with ease. The laser welding system is suitable for the repair of shapes/components of medium and large parts.

2017

Now available at joke - Deburring Course

In addition to polishing, the deburring sector is also gaining importance. The requirements for deburring quality and process reliability are increasing. Here, we offer the possibility to close knowledge gaps through training.

2016

Big appearance at AMB - new ENESKAmicro - Deburring, Grinding, and Polishing System developed by joke

Micromotor systems, also known as electric motor systems, are mobile units for grinding, milling, and polishing. Power, flexibility, and mobility are the features that significantly facilitate the processing of even larger workpieces.

2016

Long-awaited - ENESKAlaser 750-1000 Laser Welding Device

Mobile workstation primarily for smaller repairs and joining processes with excellent results! The entire operation of the laser system is done through a convenient touchscreen interface.

2015

New joke Magic FAS Diamond Paste

It consists of a thin, easily spreadable oil-soluble carrier with hard synthetic diamonds (PCD). Due to its high material removal rates, this paste is particularly suitable for hard materials such as ceramics, carbide, cobalt, titanium, or nickel.

2021

2019

2020

2018

2017

2016

2015

2010

Udo Fielenbach becomes the new Managing Director of joke Technology GmbH and joke Folienschweißtechnik GmbH

"It is my personal ambition to build upon the foundation of tradition and values of the company, shaping the future of joke. A strong brand with a rich history and brimming with the innovation and curiosity for new products and applications."

2003

Opening of Training Center - jokeneum

All trainings are conducted by our experienced trainers. In total, we offer over 20 courses annually. You can even book courses at your own company. The options include polishing, welding, deburring, and lapping courses.

1995

New Training Offering: Polishing Course

The trainings are tailored to the participants' daily work environment, emphasizing not only theory but also practical exercises. The art of polishing is about maintaining precise geometric shape while achieving a high-gloss finish with low surface roughness.

1994

Market Introduction of Blasting Device Mikromat 50

An especially cost-effective technology for surface treatment, particularly for small series. Whether for deburring, cleaning, shaping, or surface hardening – users are familiar with and appreciate the advantages of this processing technique.

1981

Introduction of Lapping Technology

We are expanding our range with the new field of lapping. This is a surface processing process for workpieces with high process reliability and the highest surface quality, while also achieving excellent flatness.

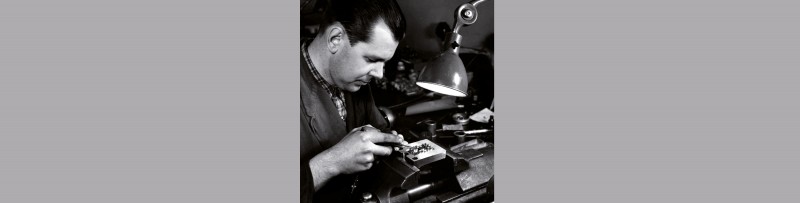

1952

Robert Kettenbaum übernahm mit joke die Vertretung für die DIPROFIL® Handfeilmaschinen.

Bis heute sind die Maschinen ein fester Bestandteil des joke Sortiments und gehören zur Grundausstattung eines jeden Polierarbeitsplatzes. Im Laufe der 50er Jahre entwickelte sich um das Duo aus JOKEFLEX® Hängemotor und DIPROFIL® Handfeilmaschine ein zunehmend ausgefeilteres Programm für Produkte zur Oberflächenbearbeitung.

1940

The abbreviated company name that is still known today was derived from the initials of the company's founders. Kettenbaum developed and built welding devices, laying the foundation for the well-known joke reputation in the field of welding technology that extends beyond borders. Eventually, the commitment expanded to serving tool-manufacturing companies and, especially, mold construction with innovative solutions and countless accessories. This marked the birth of joke's competence in surface technology.

1947

Everyone was involved if you wanted to load a welding machine from joke in the early years. The 12 1/2 kVA resistance welding machine was the company's pride and joy. Thanks to innovative control, JOKE® quickly took a leading position in spot welding. Today, with joke multiSpot 3, we weld the finest spots and seams onto the material.

Gründung

The daring man with his photography boxes: That's actually how the success story of joke began. Because a young man who realized the idea of building cameras out of old cigar boxes that worked really well had to make quite a remarkable journey in life. The man's name was Robert Kettenbaum, he studied electrical engineering and took the step towards entrepreneurship in 1940 with a repair business. That's how joke was founded: For half a decade, the Cologne-based electrical merchant Josef Joisten was a co-founder and partner in the venture.