Cookie preferences

This website uses cookies, which are necessary for the technical operation of the website and are always set. Other cookies, which increase the comfort when using this website, are used for direct advertising or to facilitate interaction with other websites and social networks, are only set with your consent.

ENESKAmicro 600 control unit PLC

By accessing the video you agree that your data will be

transmitted to YouTube and that you have read the

Privacy Policy.

€2,000.00 *

Content:

1 piece(s)

* Prices plus VAT plus shipping costs

Ready to ship today

In stock: 2 piece

Currently there are still 2 piece available!

- Order number: 0011201-AU

- GTIN 4065735061227

- eClass 6.0: 21-05-90-90

- eClass 8.1: 21-05-90-90

The new standard for grinding, polishing, milling and deburring ENESKAmicro plus PLC – the... more

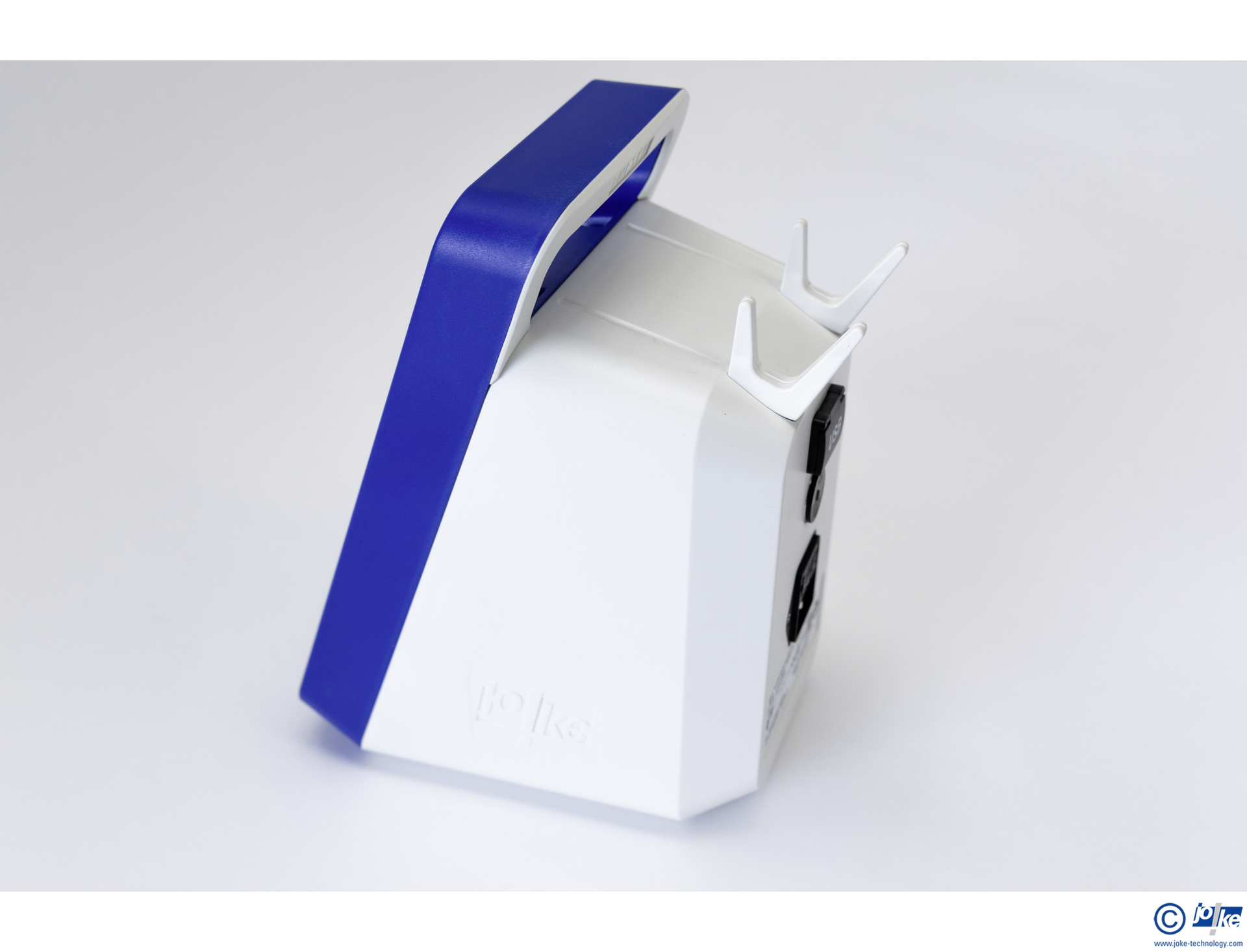

Product information "ENESKAmicro 600 control unit PLC"

The new standard for grinding, polishing, milling and deburring

ENESKAmicro plus PLC – the perfect introduction to automated operation

The in-house development by joke sets standards standards in easy external control of micromotors.

The strength of the new motor series lies in its compatibility with existing motors and control units.

More options await you in accomplishing your tasks with increased requirements in terms of flexibility and the need to optimise processes. For this purpose, joke with its new motors provides targeted solutions.

This not only enables its use in many new application areas, such as aerospace and 3D printing, but also in conventional toolmaking and mould building or in medical engineering.

Simple to operate with the touch display

The core component of the ENESKAmicro is the intelligent control unit. Intelligent because it automatically detects which micromotor is connected, regardless of whether it is from the joke family. The individual settings can be saved on the touch display with station keys.

The target speed is adjusted using the rotary knob (digital rotary encoder) or controlled using the foot pedal.

The slim design and low centre of gravity make the control unit highly stable. The newly developed handpieces achieve a higher clamping force than similar devices on the market. Created by a combination of spring and lever force that keeps the tool in position even at high speeds. The high-precision grinding of all axes and the installation of the latest-generation bearings enable a high level of true running to within less than 0.01 millimetres. Further advantages include the on/off switch and the change of rotation direction directly on the motor as well as the toolless quick-clamping function. This saves time and guarantees precise, low-vibration and fatigue-free work. joke has developed new handpieces for quick and easy clamping of the tools.

The powerful micromotor system therefore meets the technical requirements in milling in particular - wherever hard materials are machined, such as high-grade steels, Inconel and titanium for implant production.

The ENESKAmicro offers a genuine alternative to many compressed-air systems.

The facts speak for themselves:

• tremendously high cost advantage compared to expensive compressed air

• remarkably high-speed, externally variably adjustable

• low-vibration work

• quick tool changes without aids

• low noise pollution

Highlights of the units with PLC operation

• PLC mode for external programmable logic controller operation

• Standardised connection via 8-pin industrial IO connector for PLC and foot pedal

• Analogue signal input for the setpoint speed via 0-5V or 0-10V or

• Run/Stop plus digital switching between two independent speeds

• In addition, toggling between two motor channels is possible

• Digital control for right/left rotation changeover

• Standby output (OK/Error) for feedback to superordinate control unit

• Extremely simple parameter configuration through settings as for manual operation

• Optionally available test box for testing all ext. inputs (plus output) for easy introduction to the automated functions - (article no. 0 011 137)

Greater convenience and enhanced functionality with firmware v044

• Connection and detection of two BLDC motors and one DC brushed motor

• Adjustable speed in 1000 rpm increments up to 60,000 rpm

• Control circuit for optimum control behaviour with digital speed display

• Familiar clear display structure and operation via touch keys

• Simplified and switchable change of rotation direction via the handpiece

• Adjustable speed limitation when switching to anticlockwise rotation

• User support via extended device messages

• Activatable diagnostic display with information on operating parameters

Dimensions (W x H x D): 135 x 235 x 200 mm

Speed (max): 60,000 rpm

Power consumption: 250 W

Connected load: 90 - 240 V, 50-60 Hz

ENESKAmicro plus PLC – the perfect introduction to automated operation

The in-house development by joke sets standards standards in easy external control of micromotors.

The strength of the new motor series lies in its compatibility with existing motors and control units.

More options await you in accomplishing your tasks with increased requirements in terms of flexibility and the need to optimise processes. For this purpose, joke with its new motors provides targeted solutions.

This not only enables its use in many new application areas, such as aerospace and 3D printing, but also in conventional toolmaking and mould building or in medical engineering.

Simple to operate with the touch display

The core component of the ENESKAmicro is the intelligent control unit. Intelligent because it automatically detects which micromotor is connected, regardless of whether it is from the joke family. The individual settings can be saved on the touch display with station keys.

The target speed is adjusted using the rotary knob (digital rotary encoder) or controlled using the foot pedal.

The slim design and low centre of gravity make the control unit highly stable. The newly developed handpieces achieve a higher clamping force than similar devices on the market. Created by a combination of spring and lever force that keeps the tool in position even at high speeds. The high-precision grinding of all axes and the installation of the latest-generation bearings enable a high level of true running to within less than 0.01 millimetres. Further advantages include the on/off switch and the change of rotation direction directly on the motor as well as the toolless quick-clamping function. This saves time and guarantees precise, low-vibration and fatigue-free work. joke has developed new handpieces for quick and easy clamping of the tools.

The powerful micromotor system therefore meets the technical requirements in milling in particular - wherever hard materials are machined, such as high-grade steels, Inconel and titanium for implant production.

The ENESKAmicro offers a genuine alternative to many compressed-air systems.

The facts speak for themselves:

• tremendously high cost advantage compared to expensive compressed air

• remarkably high-speed, externally variably adjustable

• low-vibration work

• quick tool changes without aids

• low noise pollution

Highlights of the units with PLC operation

• PLC mode for external programmable logic controller operation

• Standardised connection via 8-pin industrial IO connector for PLC and foot pedal

• Analogue signal input for the setpoint speed via 0-5V or 0-10V or

• Run/Stop plus digital switching between two independent speeds

• In addition, toggling between two motor channels is possible

• Digital control for right/left rotation changeover

• Standby output (OK/Error) for feedback to superordinate control unit

• Extremely simple parameter configuration through settings as for manual operation

• Optionally available test box for testing all ext. inputs (plus output) for easy introduction to the automated functions - (article no. 0 011 137)

Greater convenience and enhanced functionality with firmware v044

• Connection and detection of two BLDC motors and one DC brushed motor

• Adjustable speed in 1000 rpm increments up to 60,000 rpm

• Control circuit for optimum control behaviour with digital speed display

• Familiar clear display structure and operation via touch keys

• Simplified and switchable change of rotation direction via the handpiece

• Adjustable speed limitation when switching to anticlockwise rotation

• User support via extended device messages

• Activatable diagnostic display with information on operating parameters

Dimensions (W x H x D): 135 x 235 x 200 mm

Speed (max): 60,000 rpm

Power consumption: 250 W

Connected load: 90 - 240 V, 50-60 Hz

| Dimensions (W x H x D): | 135 x 235 x 200 mm |

| Rotation speed max.: | 60,000 1/min |

| Supply voltage: | 90 - 240 V, 50-60 Hz |