Cookie preferences

This website uses cookies, which are necessary for the technical operation of the website and are always set. Other cookies, which increase the comfort when using this website, are used for direct advertising or to facilitate interaction with other websites and social networks, are only set with your consent.

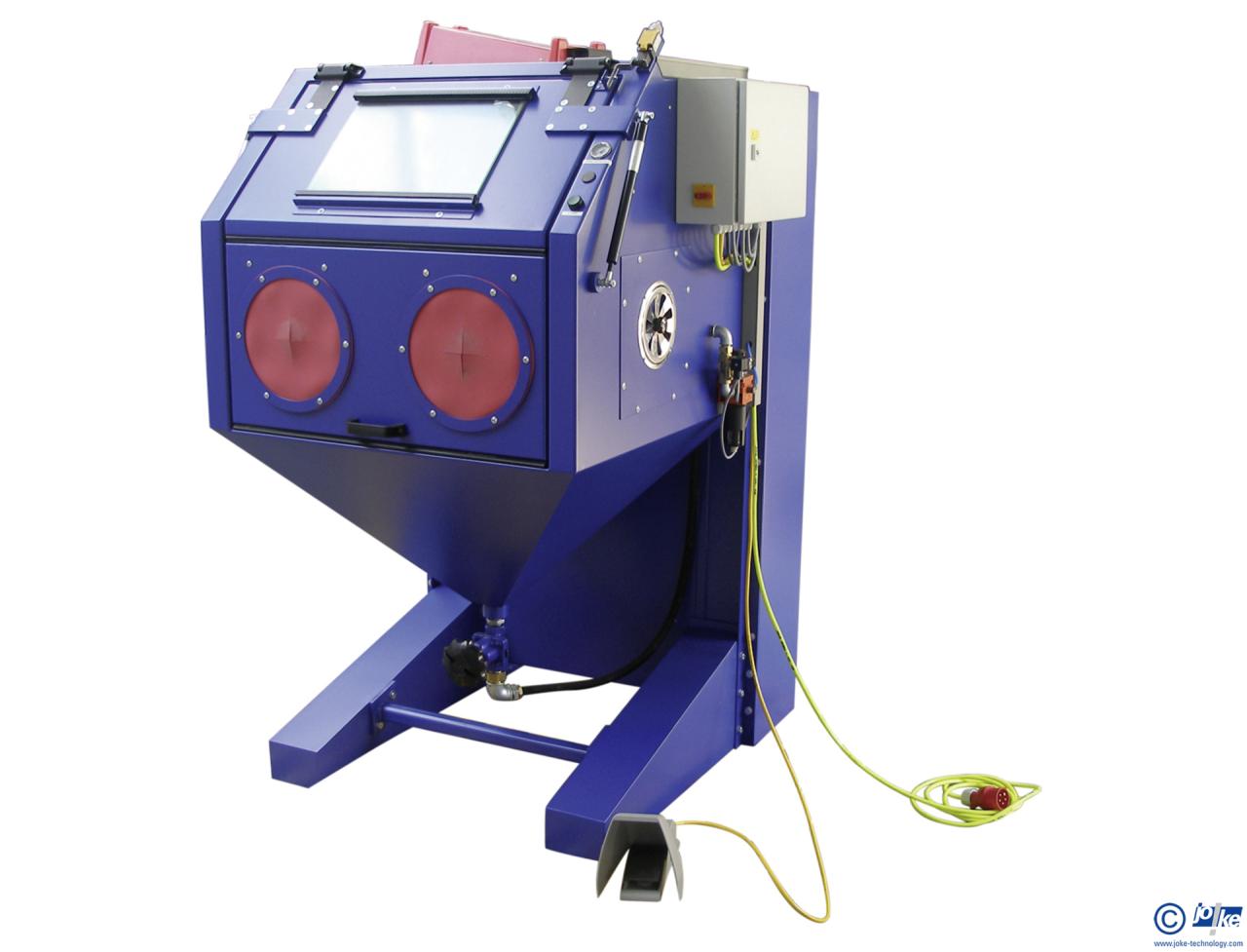

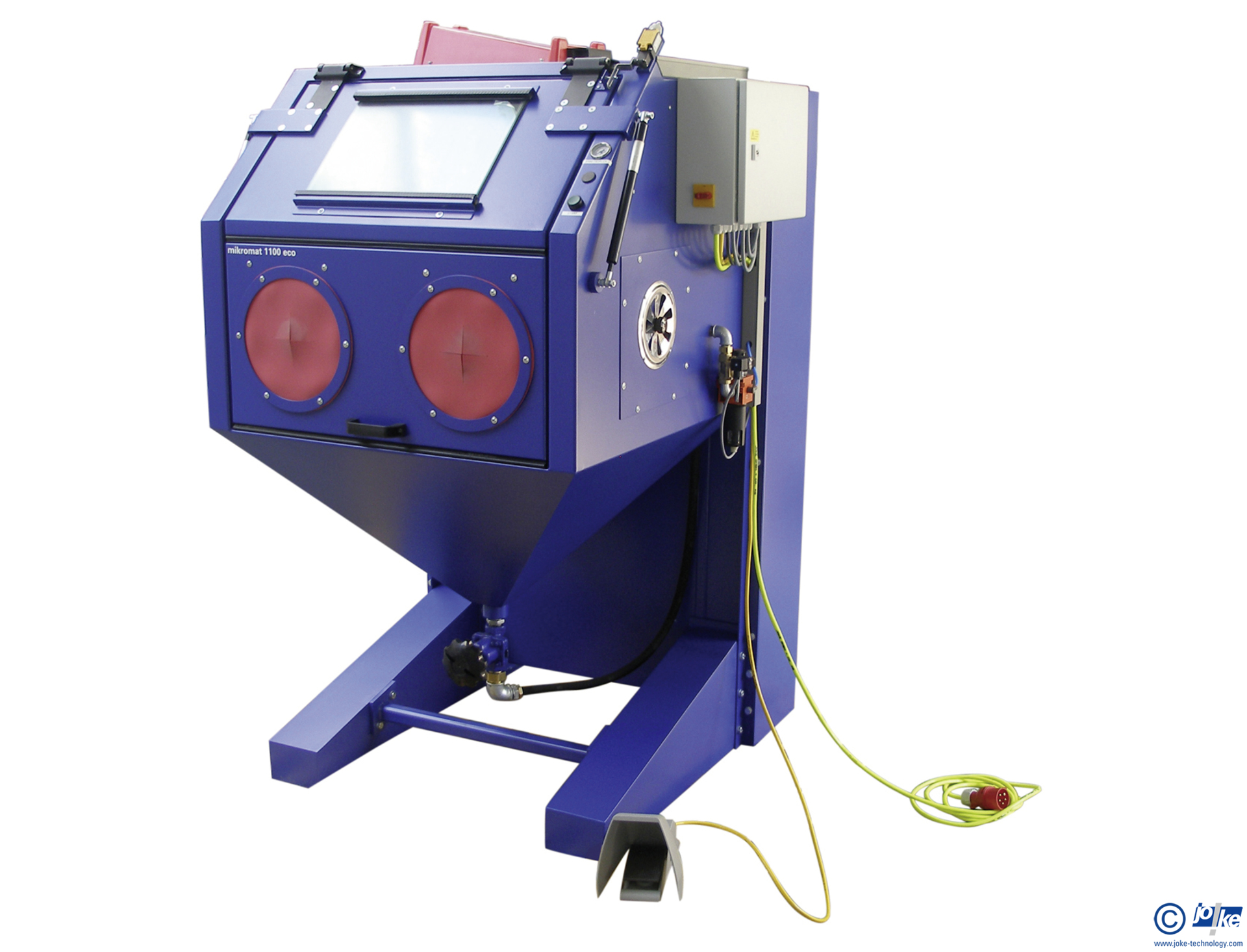

Fine blasting unit mikromat 1100 pro

Content:

1 piece(s)

- Order number: 0952500

- GTIN 4065735331115

- eClass 5.1: 36-23-11-02

- eClass 6.0: 21-12-90-90

- eClass 8.0: 21-12-90-90

- eClass 8.1: 21-19-90-90

- UNSPSC: 23281703

Fine blasting units Series “pro” The fine blasting units from the pro series are perfectly... more

Product information "Fine blasting unit mikromat 1100 pro"

Fine blasting units Series “pro”

The fine blasting units from the pro series are perfectly prepared ex-works for optional equipment. This allows ideal working conditions. They are state of the art with their LED working chamber lights. We offer every worker ergonomically adaptable working conditions in the form of the “ERGOSIZE” height-adjustable working chamber. Other highlights: fully automatic filter cleaning and frequency-controlled extraction together with the afterfilter system allow minutest quantities of residual dusts with a very low noise level.

Highlights:

• LED lighting

• compact, space-saving design

• High-efficiency filter cartridges with 8 m² filter area

• Large viewing window with easily replaceable elements

• Sensible additional equipment

• Remnants are reduced to a minimum

• also retrofittable with the following accessories: Blow-out gun, blasting gun holder, fine blasting unit microblast-A, afterfilter system and blasting shot and blasting shot control

Scope of delivery: Blasting nozzle made of hardened steel (Ø 7 mm), safety switch (no blasting shot supply when hood open), pressure controller with water separator, foot switch for starting/stopping the blasting process, exhaust air connector for connection or with an exhaust air duct of an afterfilter system, blasting gun holder

The fine blasting units from the pro series are perfectly prepared ex-works for optional equipment. This allows ideal working conditions. They are state of the art with their LED working chamber lights. We offer every worker ergonomically adaptable working conditions in the form of the “ERGOSIZE” height-adjustable working chamber. Other highlights: fully automatic filter cleaning and frequency-controlled extraction together with the afterfilter system allow minutest quantities of residual dusts with a very low noise level.

Highlights:

• LED lighting

• compact, space-saving design

• High-efficiency filter cartridges with 8 m² filter area

• Large viewing window with easily replaceable elements

• Sensible additional equipment

• Remnants are reduced to a minimum

• also retrofittable with the following accessories: Blow-out gun, blasting gun holder, fine blasting unit microblast-A, afterfilter system and blasting shot and blasting shot control

Scope of delivery: Blasting nozzle made of hardened steel (Ø 7 mm), safety switch (no blasting shot supply when hood open), pressure controller with water separator, foot switch for starting/stopping the blasting process, exhaust air connector for connection or with an exhaust air duct of an afterfilter system, blasting gun holder

| Compressed-air adjustment range: | 0.5 – 10 bars |

| Supply voltage: | 230/400 V, 5-pin plug |

| Noise level: | 75–76 dB(A), with afterfilter < 70 dB(A) |

| Filter area: | 8.0 m² |

| Lighting: | LED |

| Compressed-air connection: | Rapid-release coupling 1/2" |

| Load bearing capacity of work area: | approx 130 kg |

| Fan output: | approx. 1,000 m³/h |

| Device dimensions (W x H x D): | approx. 1,090 x 1,300 x 1,650 mm |

| Weight: | approx. 300 kg |

| Working chamber dimensions (W x D x H): | approx. 920 x 900 x 750 mm |

| Air consumption: | max. 700 l/min at 7 bars |