Cookie preferences

This website uses cookies, which are necessary for the technical operation of the website and are always set. Other cookies, which increase the comfort when using this website, are used for direct advertising or to facilitate interaction with other websites and social networks, are only set with your consent.

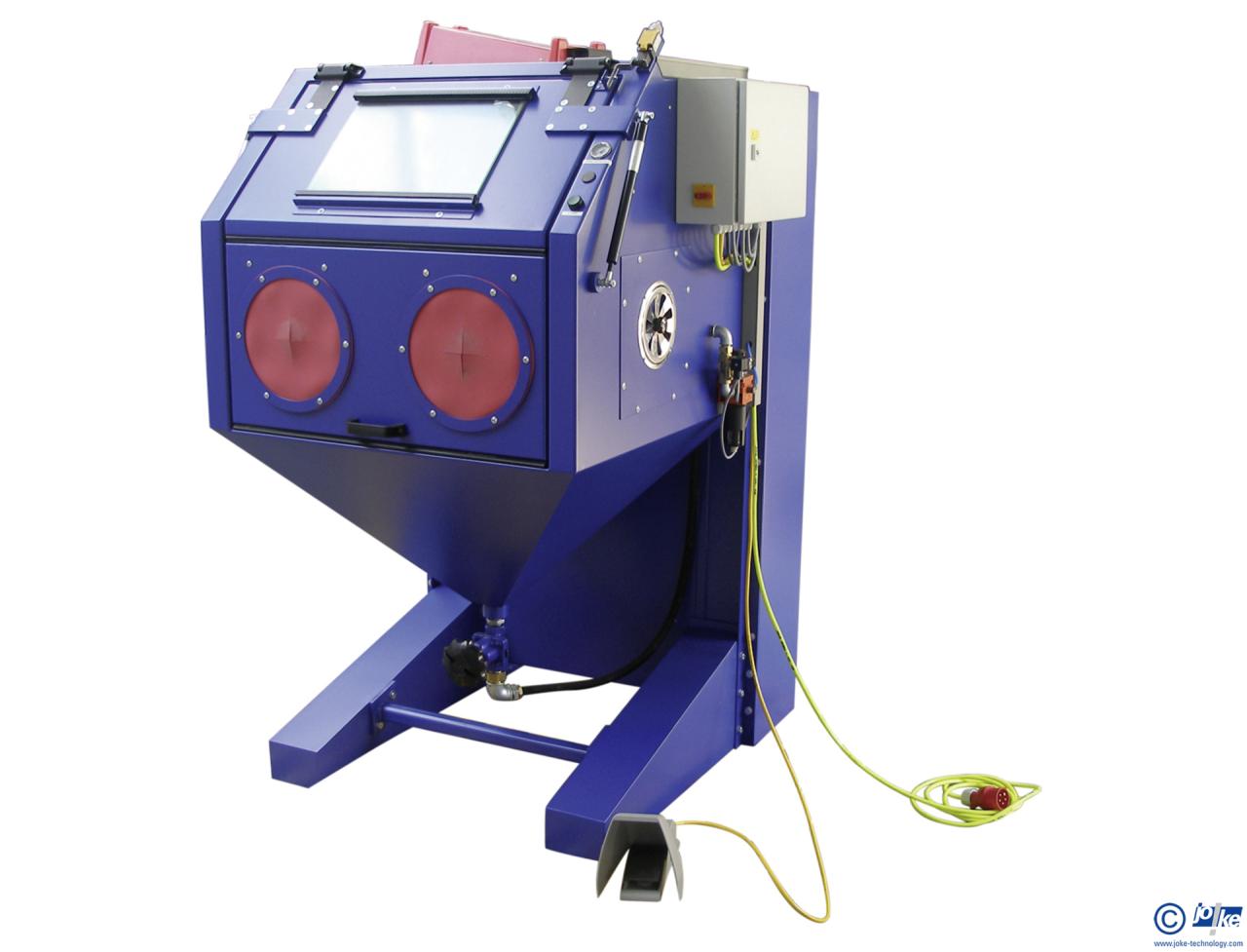

Fine blasting unit mikromat 1000 eco

Content:

1 piece(s)

- Order number: 0952200

- GTIN 4065735331047

- eClass 5.1: 36-23-11-02

- eClass 6.0: 21-19-91-90

- eClass 8.0: 21-05-90-90

- eClass 8.1: 21-19-90-90

Fine blasting units “eco” series The new, budget-priced entry level blasting unit offering... more

Product information "Fine blasting unit mikromat 1000 eco"

Fine blasting units “eco” series

The new, budget-priced entry level blasting unit offering professional quality for workshop and factory. It is highly recommended for deburring, derusting, cleaning, roughening, matting, descaling and removing of lacquer. This unit offers modern technology with many practical features at an attractive price.

Highlights:

• Compact, space-saving design

• Integrated dust exhaust for perfect visibility during the blasting process

• Blasting shot is processed in a closed loop, i. e. only dust etc. is removed, the blasting shot is recycled

• High-performance filter cartridge (up to 8 m² filter space)

• Large window

• Adjustable blasting pressure via pressure regulator

• Easy exchange of blasting shot thanks to steep funnel

• Grid with high loading capacity

• Integrated safety device

• LED work chamber illumination

• Easy self-installation of the optional equipment, even as retrofitting

Supplied with: Tungsten carbide blasting nozzle (bore Ø 7 mm), gloves with sewed-on sleeves (quick-change system), pressure regulator with water separator, safety switch (no blasting shot supplied if cubicle is open) and foot switch to start/stop the blasting process.

The new, budget-priced entry level blasting unit offering professional quality for workshop and factory. It is highly recommended for deburring, derusting, cleaning, roughening, matting, descaling and removing of lacquer. This unit offers modern technology with many practical features at an attractive price.

Highlights:

• Compact, space-saving design

• Integrated dust exhaust for perfect visibility during the blasting process

• Blasting shot is processed in a closed loop, i. e. only dust etc. is removed, the blasting shot is recycled

• High-performance filter cartridge (up to 8 m² filter space)

• Large window

• Adjustable blasting pressure via pressure regulator

• Easy exchange of blasting shot thanks to steep funnel

• Grid with high loading capacity

• Integrated safety device

• LED work chamber illumination

• Easy self-installation of the optional equipment, even as retrofitting

Supplied with: Tungsten carbide blasting nozzle (bore Ø 7 mm), gloves with sewed-on sleeves (quick-change system), pressure regulator with water separator, safety switch (no blasting shot supplied if cubicle is open) and foot switch to start/stop the blasting process.

| Compressed-air adjustment range: | 0.5 – 10 bars |

| Supply voltage: | 230/400 V, 5-pin plug |

| Filter area: | 8.0 m² |

| Lighting: | LED |

| Compressed-air connection: | Rapid-release coupling 1/2" |

| Fan output: | approx. 1,000 m³/h |

| Working chamber dimensions (W x D x H): | approx. 1,000 x 900 x 750 mm |

| Device dimensions (W x H x D): | approx. 1,110 x 1,300 x 1,650 mm |

| Load bearing capacity of work area: | approx. 130 kg |

| Weight: | approx. 300 kg |

| Air consumption: | approx. 700 l/min at 7 bars |